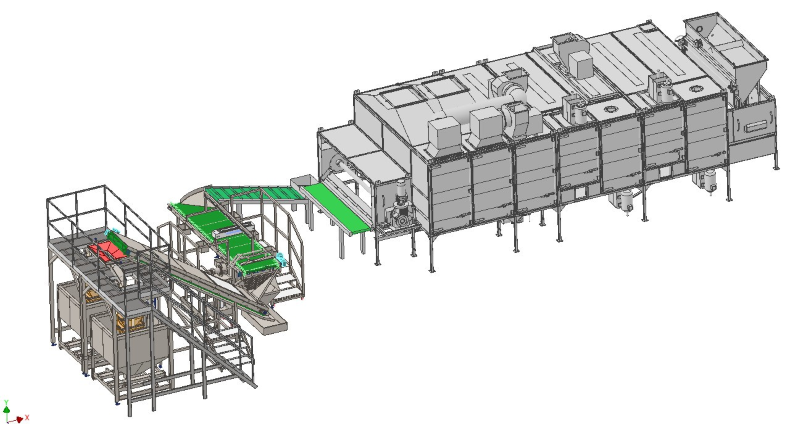

In May 2024, a multifunctional nut drying machine was jointly designed and produced by Glad and a Fortune 500 company. The designed nut varieties include cashews, almonds, macadamia nuts, pistachios, hazelnuts, and so on. Some of these nuts are coated with seasoning powder, while others are soaked in sugar, so this dryer must have compatibility. But the output is only 1 ton per hour.

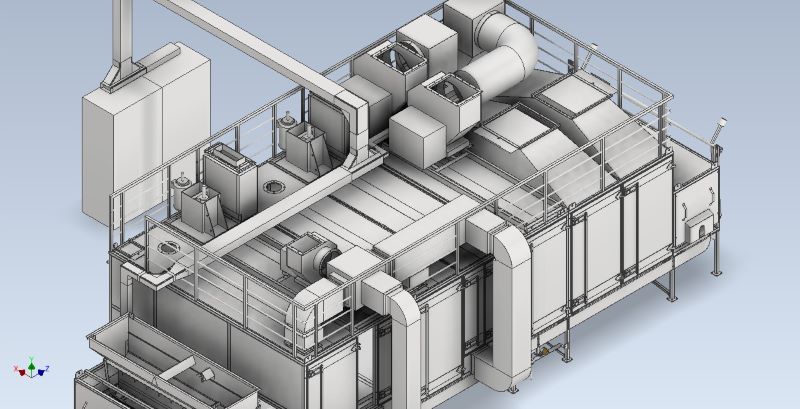

At the beginning of the design, 4 heating zones and 2 cooling zones were considered, and the direction of the air in the heating zone is alternating to maintain uniform drying effect. Due to the limited availability of the client's site, we can only consider designing the equipment to be wide and short enough, which also demonstrates our company's concept of customized customization.

Please take a look at how a unique multifunctional drying and baking machine was born!

1)Process discussion and detailed design

2)Processing and Manufacturing

3) Assemble before shipment FAT

4)Disassemble into modules and pack them in modular containers for sea freight

5)Arriving at the destination, unloading

6)Installation

7)Debugging

8)Deep cleaning of internal and external parts

The status of before production

9)Production

The temperature control in each zone is quite precise, with an error of no more than 1 degree Celsius. The following white SV is the set value